Calpeda production covers all types of pressure boosting sets: fixed speed, variable speed, and groups with one variable speed pump and the rest fixed speed pumps.

If the main quality of a pressure boosting system is reliability when supplying water, even with great differences in consumption, the application of inverter technologyhas made it possible to place energy saving at the forefront, even with pressure boosting sets.

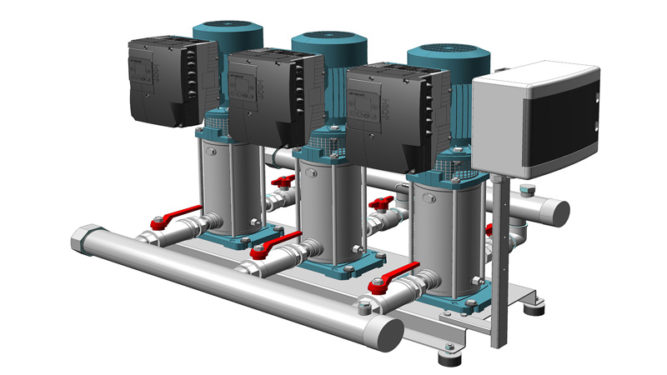

The production standard is usually characterised by sets with three pumps, but Calpeda can supply special sets with up to 6 pumps and extremely personalised, as far as both the electric and the mechanical parts are concerned.

In order to answer market requests more efficiently and quickly, Calpeda research has always aimed at optimising pressure boosting sets production, conciliating flexibility with efficiency.

To save time, both during the offer phase and the product realisation phase, the set was thought about in terms of “platform”. More specifically, the base and hydraulic part are produced to adapt to all pump models of the same family and for all the three set versions (fixed speed, variable speed, mixed speed).

It is important to highlight that this development fully protects flexibility, because the wide range of models proposed remains unchanged. In addition, as far as the hydraulic parts (valves and manifolds) are concerned, the need for adaptation led to the choice of the best quality parts for each component, making it possible to guarantee that clients have higher performing groups at competitive costs.